Innovative polishing technology

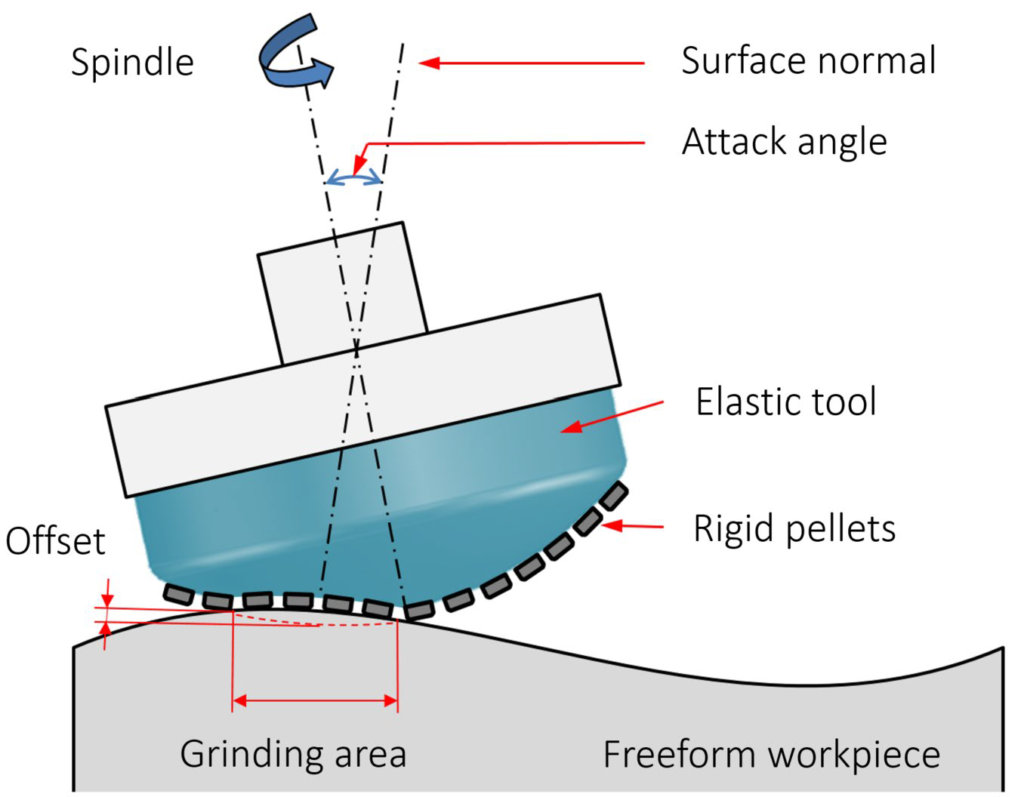

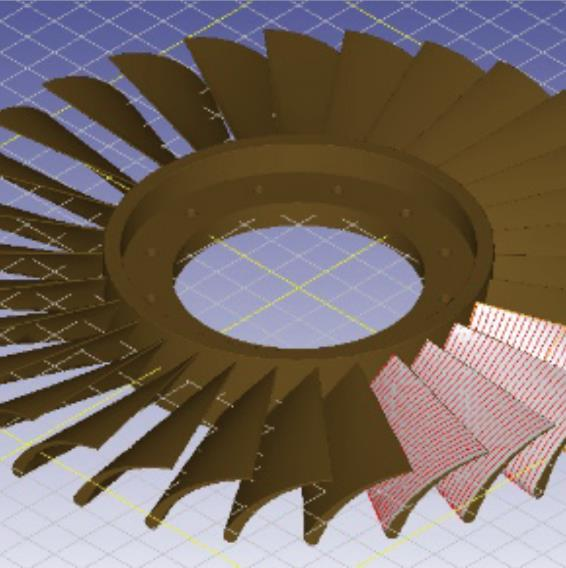

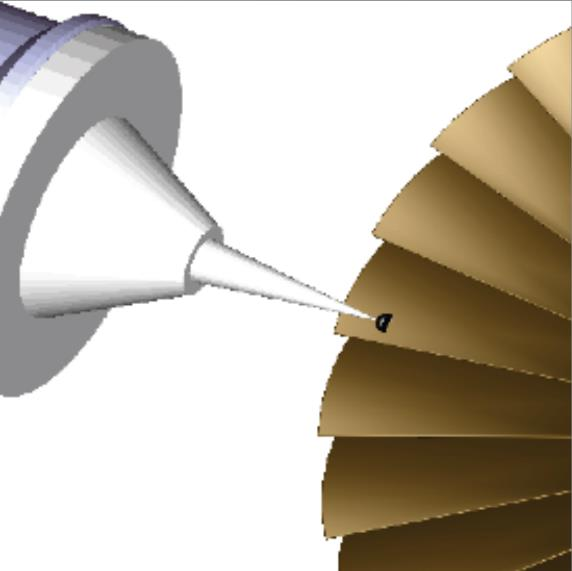

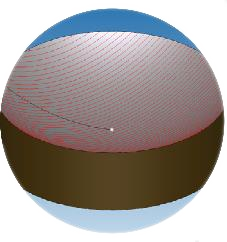

TIZSAG as an innovative polishing technology allows the use of existing machine tools for the exact machine polishing of complex shapes. The kinematics of the process is well described in the graphic below. A flexible tool with abrasive elements at an angle to the surface rotates around its axis and moves along the workpiece.

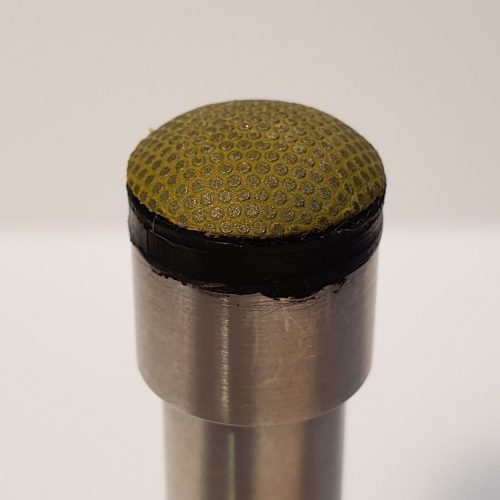

• The new tools consist of a flexible material covered with stiff granules that carry abrasives

• The grinding area is controlled by the tool offset to the surface

• Grinding direction and speed are controlled by the rake angle and spindle

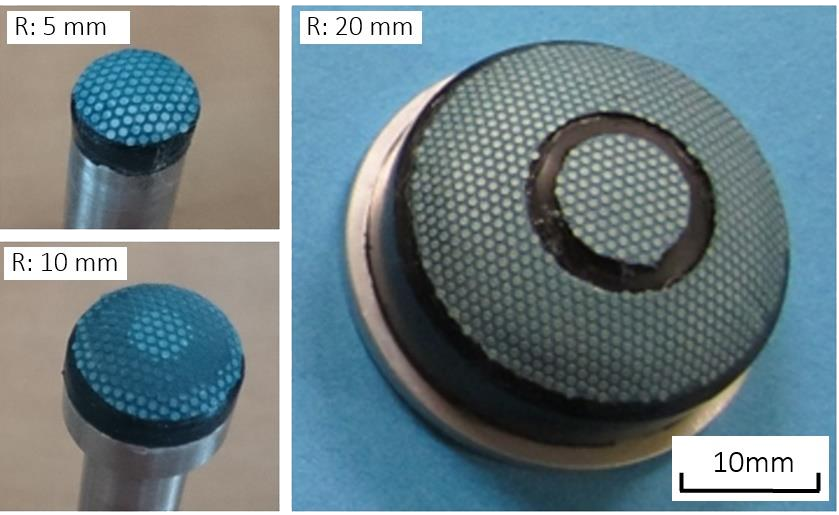

Examples of SAG tools with different diameters

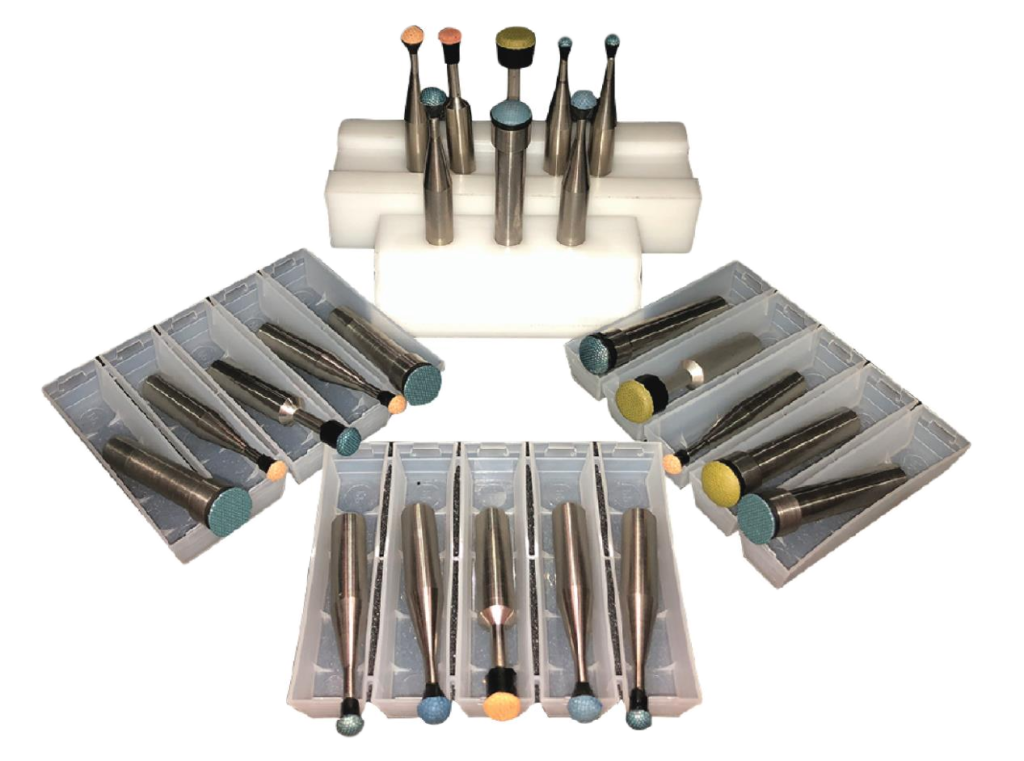

Dedicated tools

We offer a wide selection of dedicated grinding and polishing tools

We can design and manufacture special tools

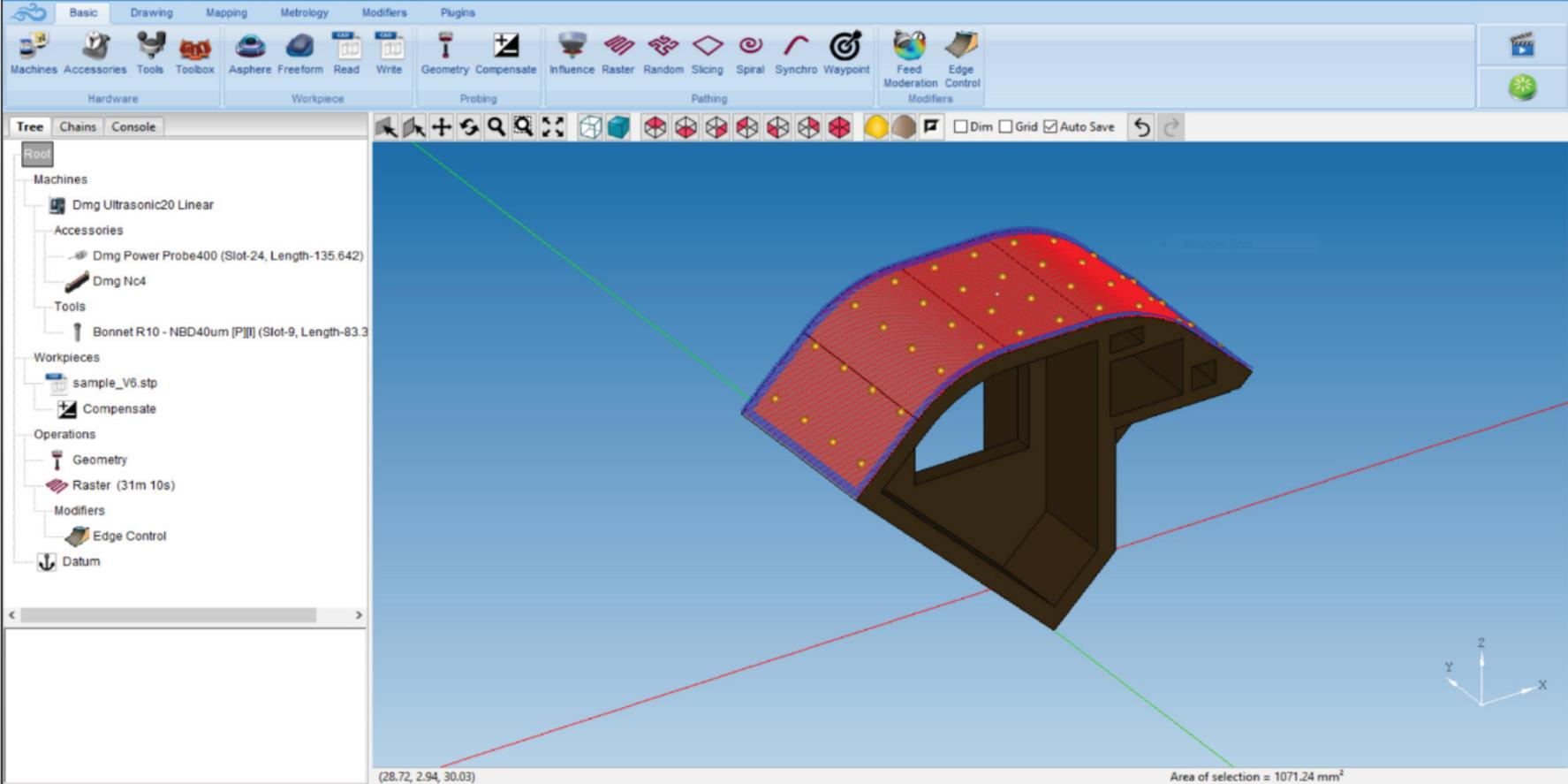

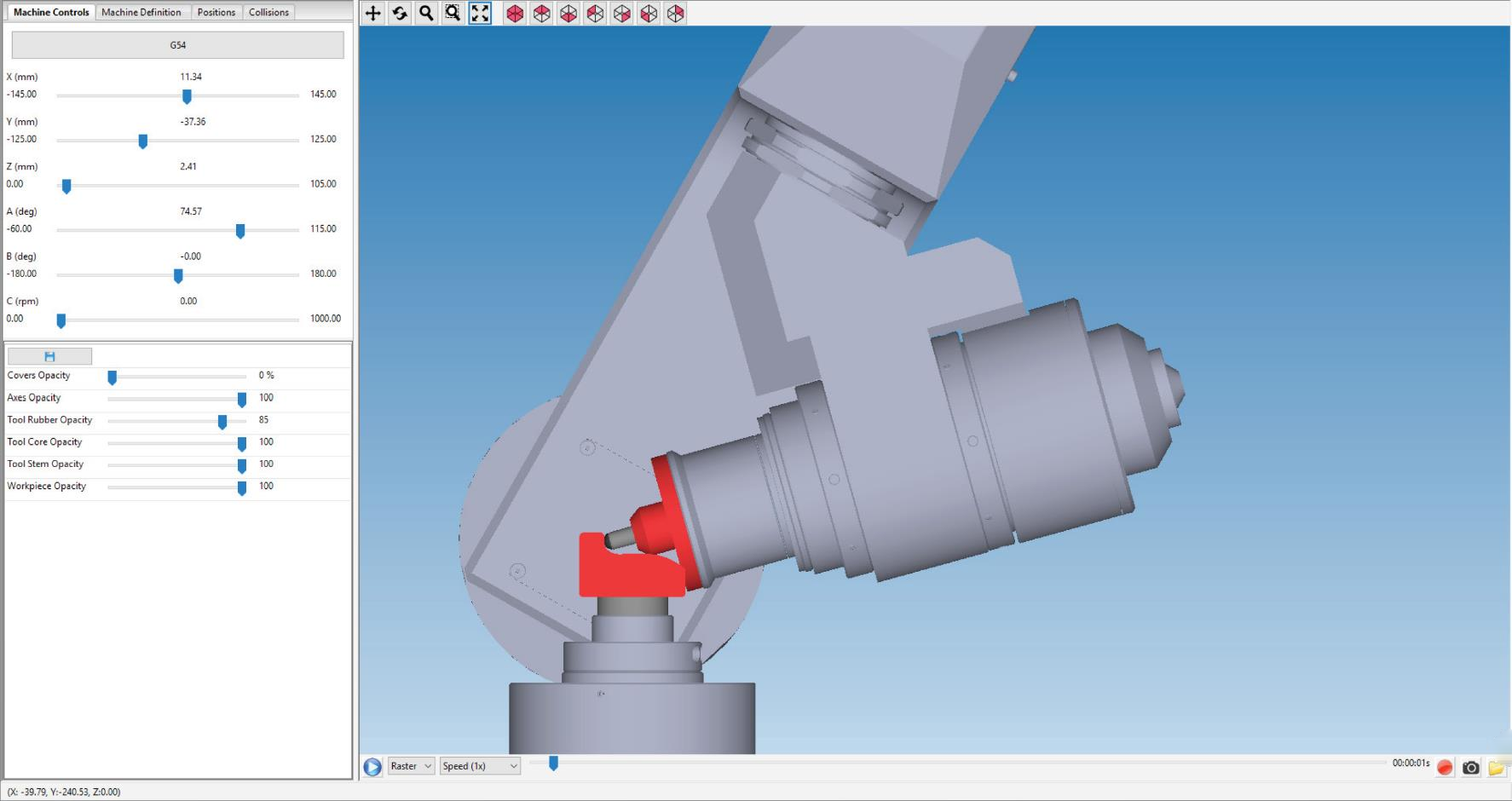

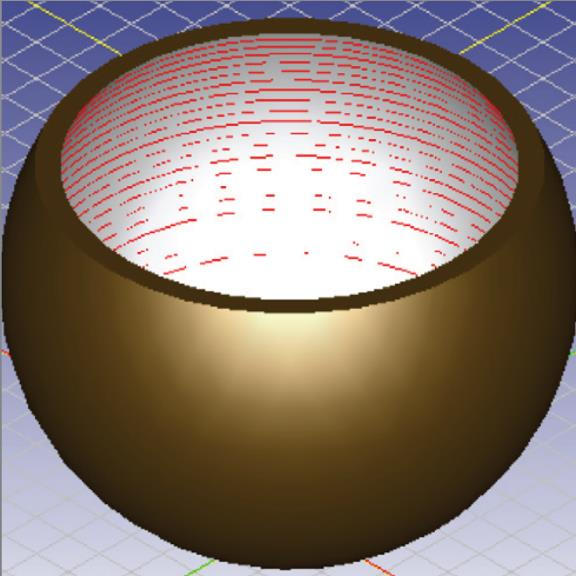

CAM software

We have dedicated CAM software that allows you to load an existing CAD model, define the machine and tooling, generate NC programs for measurements and the grinding process, and simulate. The software allows you to perform simulations with automatic collision detection.

Główne cechy oprogramowania CAM

• Quickly generate complex toolpath strategies

• Various toolpaths supported

• Automatic toolpath calculation for complex geometries

• Automatic toolpath calculation for simple geometries

• CNC generation for a wide range of machines

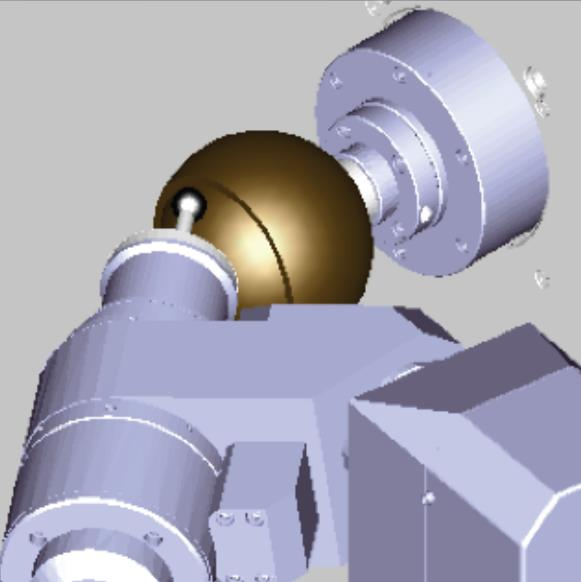

Use of existing machine tools

We give the possibility of using it in CAM

• New and existing machines

• Standard and special SAG tools

• Special models of workpieces

• New toolpath generation algorithms

• And other add-ons that can be developed for the customer

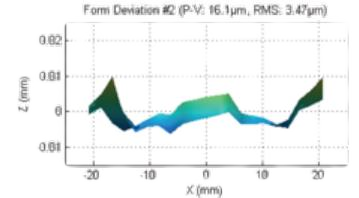

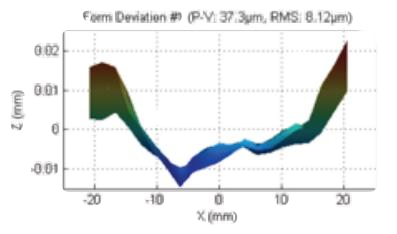

Examples of grinding results

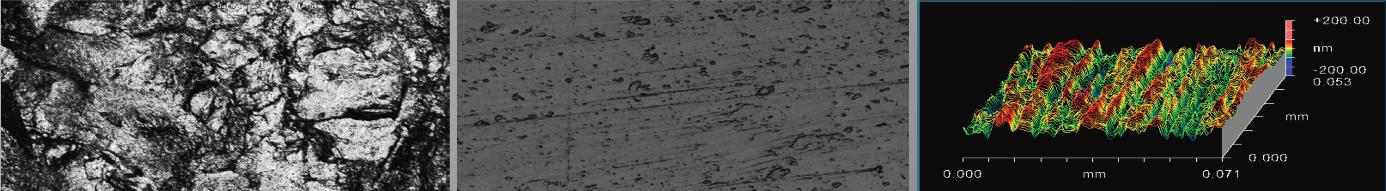

CVD SiC

Initial state

Condition after grinding

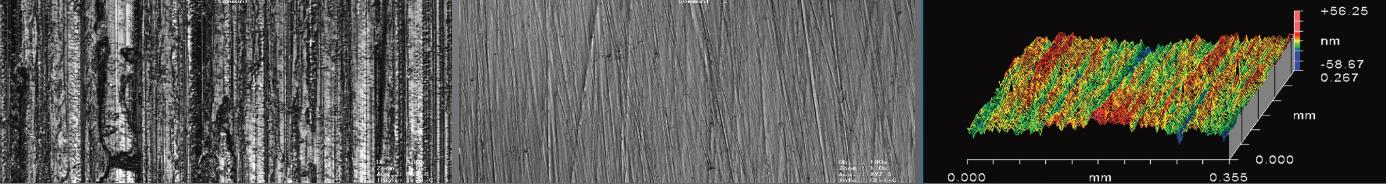

STAVAX

Initial state

Condition after grinding

Ti6Al4V

Initial state

Condition after grinding

Co-Cr

Initial state

Condition after grinding

INCONEL

Initial state

Condition after grinding

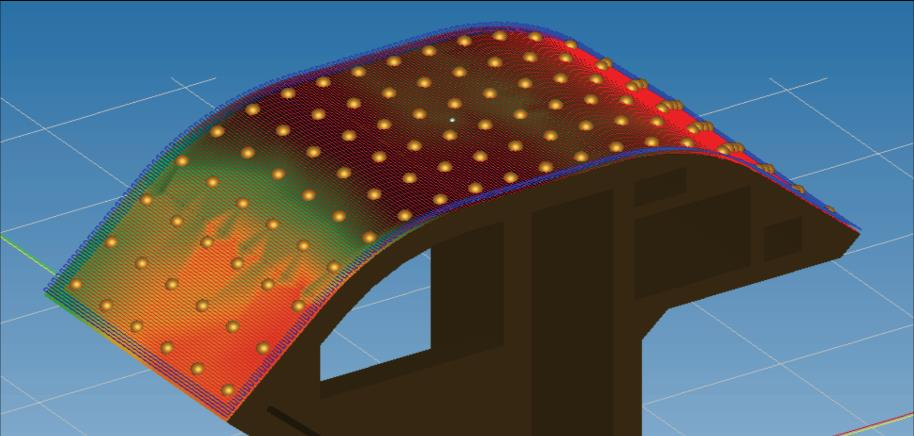

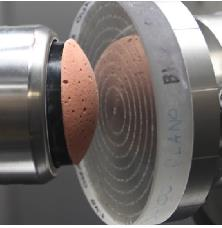

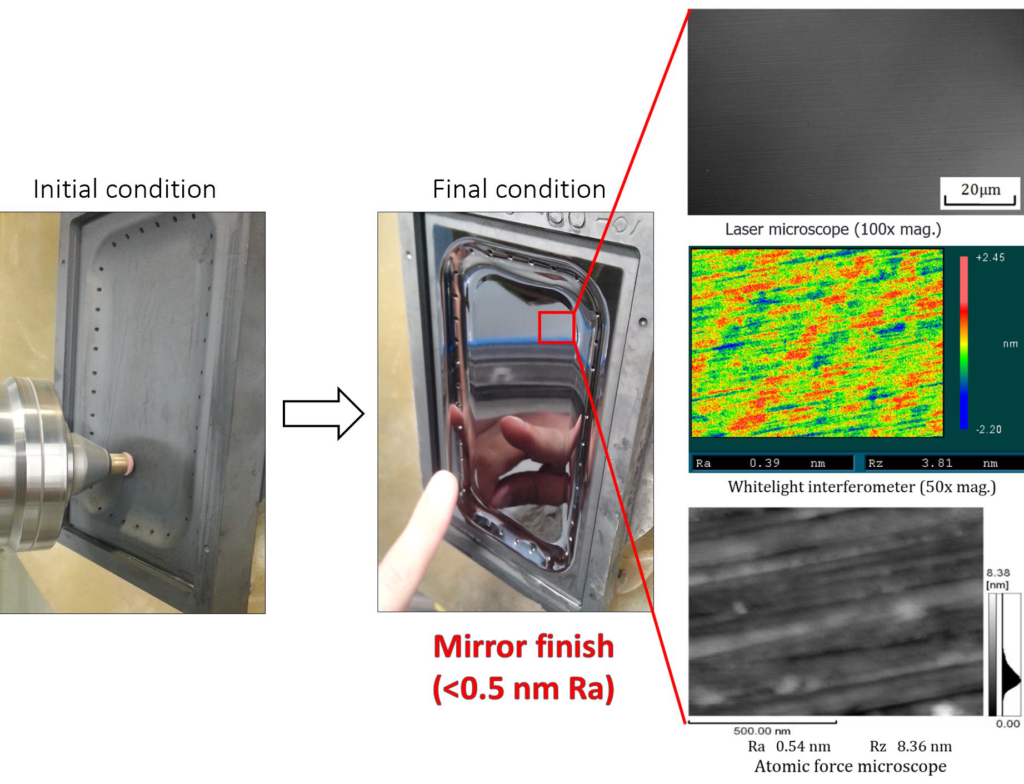

Case Study

Examples of the use of SAG for polishing molds

Case Study

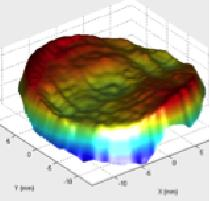

Grinding of a graphite mold coated with CVD silicon carbide

CVD SiC Coated Graphite Mold (For Glass Forming).

Roughness reduced from 4 µm to 0.5 nm Ra.

Contact form

Make an online appointment with an advisor

If you have any questions, we remain at your disposal

Technical Department:

technolog@tizimplements.com

Sales and Marketing:

bok@tizimplements.com